Solar PV panels produce a type of electricity known as “Direct Current” or DC. Most houses, however, use “Alternating Current” or AC. One of the reasons for this is because AC is better suited to be transmitted over long-distances. The role of inverters in solar PV is therefore to convert the electricity generated by your solar panels (DC form) into AC form.

Solar inverters must also comply with local regulations with respect to how they feed excess electricity generated by your solar PV back to the grid. For example, inverters should automatically disconnect from the grid if there is a power cut.

Each inverter has its own characteristics. Before buying one, you should consider the following factors:

- What is the size of your inverter and how much DC power (in terms of wattage) can it handle safely from the solar PV?

- What is the maximum input voltage that the inverter can handle before there is any damaged electronics?

- What is the minimum amount of voltage that your inverter requires before it is able to start working? What is the optimal voltage range that the inverter can take in from the solar PV?

Solar PV has a nameplate capacity but in real life conditions, there is a very high chance that your solar PV system will not generate as much as what is stated on the nameplate capacity. Therefore, inverters tend to have a power rating smaller than an solar PV array. For example, for a 3 kWp array you might want to consider an inverter size between 2.4 kW and 3.3 kW.

Home solar inverters are never 100% efficient at electrical conversion. This is because they need power to run, which is fed by the DC electricity generated by the solar PV. Their typical efficiency ranges between 93-96%.

Another aspect to consider is the voltage produced by your solar PV vs. what your grid or batteries accept. For example, if your solar panels under STC conditions produce 17.6V @ 7.39A (130W) and your home battery is rated at 12V (batteries work with specific voltages), then your real power stored would be much lower than the stated solar output. Your solar PV voltage needs to match the battery voltage in order to work properly. Without any voltage conversion, it would produce 12V @ 7.39A (88.8W), which is around 41 watts lower than what you could be obtaining under ideal conditions.

For this reason, advanced systems such as Maximum Power Point Tracking (MPPT) were created. These charge controllers optimize the voltage and amperage of the solar PV system to match what is accepted by your home batteries while generating the maximum amount of power. For example, if your solar PV panels can generate 130W, and we need to match the battery’s 12V, the ideal amperage would be 130W ÷ 12V = 10.83A. An MPPT controller performs this conversion with about 95% efficiency, so you’d actually get around 123.6W (12V × 10.3A), which is significantly better than the 88.8W without MPPT.

If you don’t have a battery at home or you plan to integrate your solar PV directly to the grid (known as grid-tie PV systems), MPPT will help you match your grid voltage. In North America, with 120V AC grid voltage, the same 130W solar panel output would be converted to approximately 126W AC (97% efficiency), delivering about 1.05A at 120V AC. In Europe, where the grid voltage is 230V AC, the same power would be delivered at about 0.55A (126W ÷ 230V). This conversion process in grid-tie systems is typically more efficient than battery-based systems since it requires fewer conversion steps.

Note that MPPT are not inverters, they are charge controllers. They work with DC electricity. Their job is to adjust and optimize the voltage and amperage from the solar panels to match what the batteries need while maximizing power output. For grid-tie systems, a separate grid-tie inverter (which includes MPPT functionality) is needed to convert the DC to AC grid voltage.

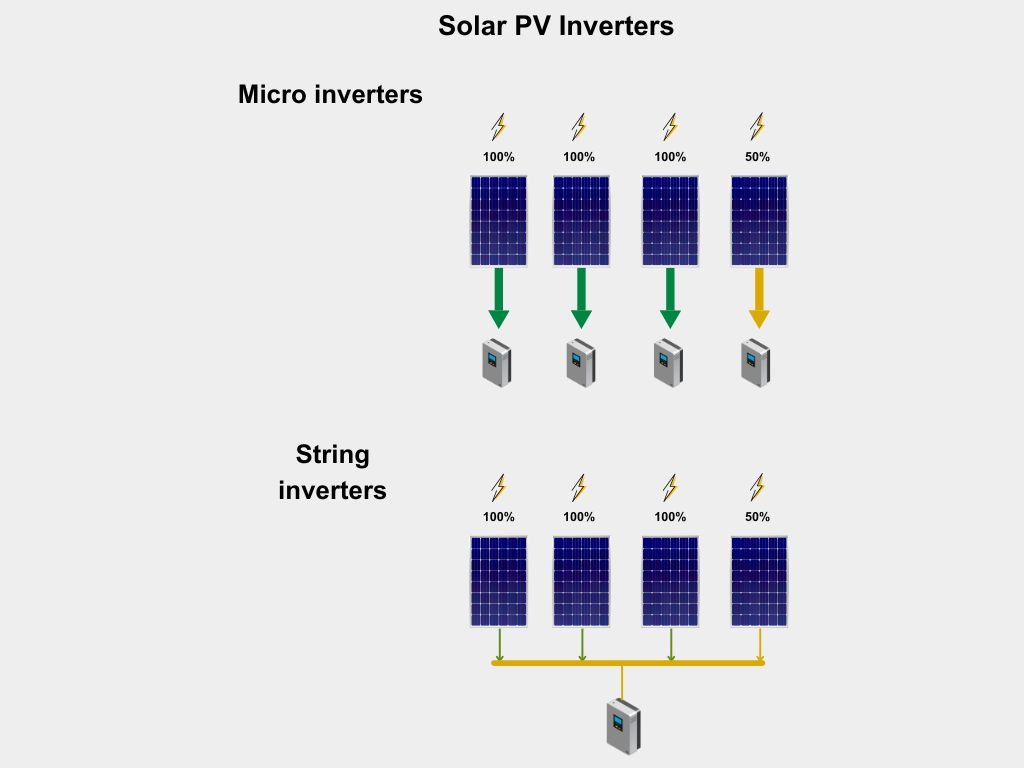

Grid-tied inverters can either be linked to a number of solar PV panels (known as central or string inverters) or be linked to one or two solar PV panels, which in this case are called micro-inverters.

String inverters work best when all solar PV panels in the string have the same characteristics and operate under uniform conditions. However, in cases where panels experience different operating conditions – such as varying tilt angles, partial shading from trees or structures, or different orientations – power output can be significantly reduced across the entire string. This happens because panels in a string are connected in series, and like a chain, the string’s performance is limited by its weakest link (the panel producing the least power). For such installations, there are two solutions: either split the panels into multiple strings with separate string inverters (grouping panels with similar conditions together), or use microinverters/power optimizers that can handle each panel independently, allowing maximum power production regardless of varying conditions across the array. String inverters are also a cost-effective choice for households with limited budget. Their cost for a residential system run about 1/4 of what the panels will cost.

Microinverters are small inverters installed directly on or near each individual solar panel. They perform the same fundamental task as string inverters – converting DC electricity into AC power – but at the panel level rather than the system level. The key advantage lies in their independent operation: if one panel’s performance is reduced (due to shading, debris, or malfunction), the other panels in the system continue to operate at their maximum power output. This independence makes the overall system more resilient to individual panel issues, unlike string inverters where a single underperforming panel can reduce the output of the entire string. Microinverters typically have longer lifespans than string inverters, often matching the 25-year warranty of the solar panels themselves. Other benefits of micro-inverters include having simpler and cheaper installation than with string inverters.

However, micro-inverters’ enhanced performance and reliability comes at a higher upfront cost compared to string inverter systems. Since it is still a relatively new technology, there is a limited number of manufacturers. Lack of expertise in many countries is a significant problem that discourages homeowners from installing them.